LED Circuit Boards

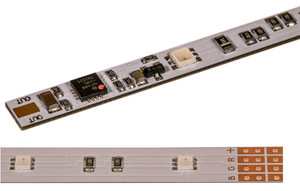

LED circuit boards consist of a carrier material that is equipped with LEDs and other electronic components. In addition, there are tin-plated copper surfaces that serve for soldering the cables.

The hansen LED circuit boards are available in series and parallel connection (12 V).

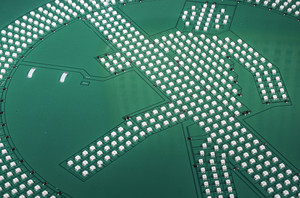

Rigid PCBs with a glass-fibre reinforced carrier made of epoxy. These boards are rigid and cannot be bent. This rigidity has the advantage that the boards can be easily processed, they stay in the desired position. On the other hand, the length is limited, especially when several blanks are soldered together.

Aluminium core blanks are mounted on a stable carrier made of aluminium. They are also rigid and can dissipate heat well (cooling). This is why high-power LEDs are usually mounted on aluminium core boards.

Flexible PCBs consist of a very thin epoxy material that allows bending (within limits). This is advantageous if the substrate has a slight curve. Several elongated PCBs can be soldered together to form a longer unit.

The size, shape and assembly of the board is determined by the "layout", which is determined by hansen creates. Customised layouts can also be produced. Whether a customised PCB is economically justifiable must be checked when an enquiry is made. This depends on the size and the number of pieces.

The conductor tracks on the PCB can only conduct the current to a limited extent. As the current increases, the heating of the conductor path increases, which results in a greater voltage drop. Therefore, the length of the circuit board track that is supplied via a single power supply point is limited. This should be taken into account especially with 12 volt PCBs (see maximum connection lengths).

In their raw state, assembled PCBs are not insulated, neither against moisture nor against contact. There are three possibilities for insulation:

- impregnation with UV-curing varnish (moisture protection)

- shrink tubing (protection against contact)

- encapsulation (protection against moisture and contact)